PRECISION PATTERNS & MOULDS DELIVERING COMPLETE TOOLING SOLUTIONS

At Hayward GRP, we leverage over 40 years of expertise in Glass Reinforced Plastic (GRP) to provide exceptional tooling and moulding solutions. Our dedicated in-house team of skilled pattern and mould makers, supported by our trusted partner network of CNC specialists and material experts, is equipped to execute even the most intricate projects efficiently, economically, and without compromise.

We don’t just manufacture tooling; we shape possibilities. From early design input to final delivery, we work closely with you to ensure that every stage aligns with your vision, reducing costs, enhancing functionality, and achieving an outstanding finish.

COMPLETE TOOLING SOLUTIONS FROM CONCEPT TO PRODUCTION-READY REALITY

Whether you bring us a sketch, CAD file, or prototype idea, our first step is always to listen. We work to understand the goals and technical requirements of your project in detail. That insight enables us to advise on design feasibility, mouldability, and component integration early in the process, saving time, improving performance, and minimising tooling costs.

Together with our extended team of industry partners, we can scale, customise, and enhance your tooling solution to meet exacting standards in both one-off commissions and volume production.

PRECISION MASTER PATTERNS CRAFTED BY HAND OR CNC MACHINED

Our timber and foam master patterns are meticulously handcrafted to replicate your finished product right down to the finest surface detail and finish. Where required, we also collaborate with local pattern makers equipped with 3- and 5-axis CNC machining capabilities to accelerate lead times and precision-engineer complex designs.

From traditional craftsmanship to digital sculpting and model making, we ensure your project starts on the strongest possible foundation, a master pattern engineered for success.

PRODUCTION MOULDS BUILT TO PERFORM, ENGINEERED TO LAST

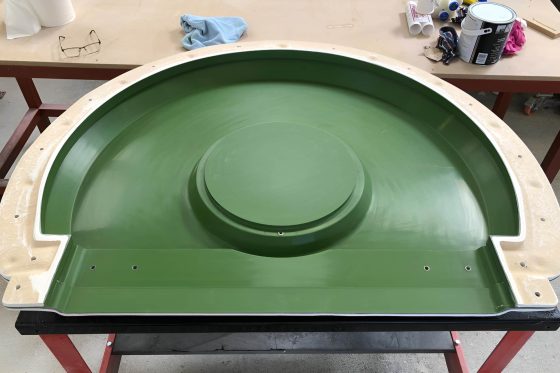

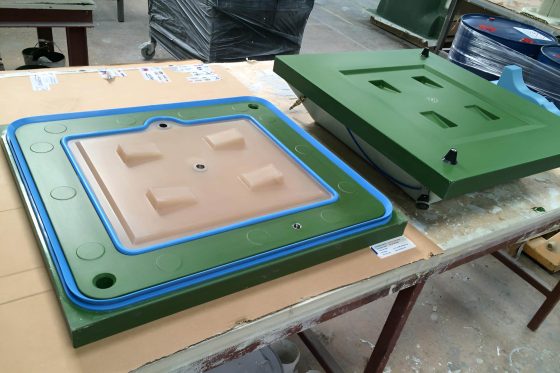

From the master pattern, our engineers create high-quality GRP/fibreglass production moulds that form the foundation of every component. We specialise in producing complex, multi-piece moulds with superior surface finishes and structural integrity, as the quality of the mould directly influences the quality of the end product.

Using only vinyl ester and rapid tooling materials, our moulds ensure dimensional accuracy, extended service life, and consistent quality. We also manufacture direct tooling, pattern moulds, and rubber tooling, offering full flexibility for your specific application.

WHY CHOOSE HAYWARD GRP? FOUR DECADES OF PROVEN EXPERIENCE

At Hayward GRP, we have built our reputation on delivering complex, bespoke and engineered moulding solutions for a wide variety of sectors. Our deep understanding of GRP technology, materials, and processes allows us to confidently deliver tooling and components that meet rigorous standards, tight deadlines, and demanding specifications.

We are proud to maintain multiple internationally recognised accreditations:

- ISO 9001 – Quality Management

- ISO 14001 – Environmental Responsibility

- ISO 45001 – Health & Safety

- ISO 27001 – Information Security

- Cyber Essentials Plus – Cyber Security

THE HAYWARD GRP DIFFERENCE A COMPLETE COLLABORATIVE APPROACH

We don’t just create patterns and moulds; we deliver solutions. From the drawing board to the final fix, we take full ownership so you can focus on results. Some of our key services include:

- Design Assistance & Consultancy

- Composite Calculations & FEA Analysis

- Traditional & CNC Pattern Making

- Tooling design & mould manufacture

- GRP Mouldings & Structures

- Metal Fabrication & Component Integration

- Project Management & Quality Assurance

- Worldwide Delivery & On-Site Installation

PATTERNS & MOULDS GALLERY FILM A SHORT SHOWCASE OF WHAT WE DO BEST

Take a moment to view our short Patterns and Moulds Gallery film, a curated visual showcase of our tooling solutions across varied applications; be sure to turn up the volume for the complete experience. To explore more, visit our project pages to discover examples of our team’s work across diverse sectors, scales, and design requirements.

Whether you’re at the initial idea stage or ready to move into manufacture, we’re here to help; contact our team today to start the conversation.

Call us on 01323 679555 or email info@haywardgrp.co.uk

Alternatively, click the link to GET IN TOUCH

Get In Touch