Innovative Shaping Solutions – Precision Patterns and Moulds for Bespoke Fibreglass Moulding

With over 35 years’ experience within our market sector and employing a team of highly skilled and dedicated pattern makers, mould makers and composite engineers, we are able to produce a wide range of patterns, moulds, and GRP / fibreglass mouldings to meet our customer’s exact requirements. To increase our capabilities we also work alongside our Partner Network of companies (Industry leaders) with a common goal of product excellence, it’s this quality orientated customer service that has made us partners to industry, a real future resource for all of our customers’ requirements.

Our initial approach is to gain a thorough understanding of your needs. Our highly skilled team will guide you through the various processes to exactly achieve your goals. During these initial discussions with you, we can advise on design criteria and feasibility for such matters as mould-ability and the addition of peripheral components if required. Our early input can greatly improve functionality and appearance whilst reducing tooling and component costs.

Precision Master Patterns

From a design brief, concept drawing, or CAD model, a timber or foam master pattern is produced to replicate the finished product exactly, including the surface texture and finish. We use traditional methods to construct master patterns in-house to clients requirements, but we also work with a number of local pattern making companies with 3 & 5-axis CNC capabilities, allowing efficient use of resources and specific skill sets, resulting in quality patterns and a quick turnaround. We also work alongside sculptors to produce that something special.

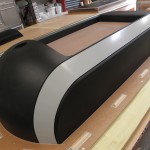

Production moulds & Tooling design

From the master pattern, a heavy duty GRP / Fibreglass production mould is produced to enable the manufacture of the finished products. Our in-house ability to produce complex, multi piece production moulds with high quality finishes is key, as the quality of each moulded component is a direct reflection of the mould itself. Controlling critical dimensions and shape is a result of moulds that are properly manufactured and structurally supported. Equally important is the type and quality of materials employed during mould construction. We only use vinyl-ester and RTS (Rapid Tooling Systems) which deliver mould longevity and good gloss retention. We also manufacture direct tooling / pattern moulds and rubber tooling, when required.

We can provide any of our capabilities as stand-alone services or we can provide a “single source solution”, from concept through to project completion and beyond. Hayward Grp bring to the table manufacturing knowledge and years of composite experience, along with offering customers “knowledge partnerships” in which we can advise on feasibility through to Design, Manufacture, Installation and provide a complete after sales and maintenance package if required.

To find out more about our services and what we can do for you, get in touch today. We welcome the opportunity of discussing your next project or product requirements. You can telephone our sales team Free on 01323 679555. Alternatively, if your query is more complicated, or you would like us to contact you, please use the contact form and we’ll be happy to call you back.

- Fibreglass Mould Makers

- Pattern Makers

- Precision Pattern Makers

- Master Pattern Makers

- GRP Pattern Making

- Fibreglass Product Fabrictors

- CNC Pattern Making

- Pattern Makers UK

- GRP Tooling

- Prototype Patterns

- Engineering Pattern Makers

- Master Pattern Makers

- Fibreglass Model Makers

- Direct Tooling

- Pattern Mould Manufacturer

- Rubber Mould Makers

- Production Tooling

- Composite Mould Makers

- Precision GRP Tooling

- GRP Mould Makers

- Fibreglass Mould Tool Makers

- GRP Tooling and Jigs

- Production Tooling

- Fibreglass Pattern Making